Overview

Essential details

Applicable Industries:

Garment Shops, Manufacturing Plant, Food & Beverage Factory, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Food & Beverage Shops, Advertising Company

Showroom Location:

Turkey, Philippines, Brazil, Peru, Indonesia, Thailand, UAE, Algeria, Sri Lanka, Uzbekistan, Malaysia

Condition:

New

Machine Type:

Bag Forming Machine

Bag Type:

Soft Loop Handle Bag

Material:

Paper

Computerized:

NO

Place of Origin:

Zhejiang, China

Brand Name:

WITY

Model Number:

ZB1100A

Voltage:

380V

Dimension(L*W*H):

7500*2200*1500(mm)

Weight:

4T

Warranty:

1 Year

Key Selling Points:

Competitive Price

Marketing Type:

Ordinary Product

Machinery Test Report:

Provided

Video outgoing-inspection:

Provided

Warranty of core components:

1 Year

Core Components:

Motor, PLC, Bearing

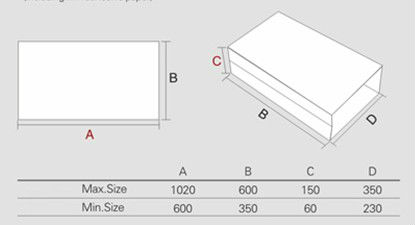

Max sheet:

1020x600mm

Min sheet:

600x350mm

Paper thickness:

150-350gsm

Speed:

70 bags/min

Bottom thickness:

60-150mm

Glue type:

Hot-melt glue

After Warranty Service:

Video technical support, online support, Spare parts, Field maintenance and repair service

Local Service Location:

Philippines, Brazil, Peru, Indonesia, Malaysia, UAE

After-sales Service Provided:

online support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service

Certification:

380V/50HZ

Supply Ability

Supply Ability

30 Set/Sets per Month

Packaging & delivery

Packaging Details

Anti-rust inside packaging, and standard outside wooden packaging for export.

Port

Ningbo

Picture Example:

Lead time:

Quantity(sets) 1 - 1 >1 Lead time (days) 30 To be negotiated

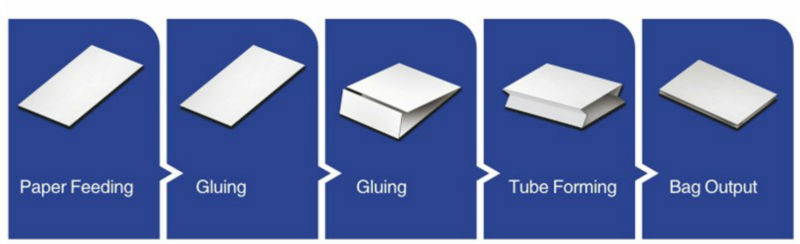

Video Description

ZB1100A Paper Bag Making Machine

Description:

ZB1100A paper bag making machine is suitable for making different size of bags from different types of paper (raw material should be die-cut and creased paper sheets). Material can be automatically delivered by feeder, and the speed can be controlled by inverter. Through the process of automatic positioning, gluing, folding, and pressing, the finished product will be output as paper tube.

Features:

- This machine adopts presice automatic positioning syetem, and the speed is controlled by inverter.

- With presice screw adjustment, which can greatly reduce the adjusting time for making bags with different sizes.

- Adopts hot-melt gluing system, makes gluing process fast and firm.

Specifications:

Max sheet | 1020x600mm L×W |

Min sheet | 600x350mm L×W |

Paper thickness

| 150~350gsm |

180~300gsm for Art paper | |

Speed | 70 bags/min |

Bottom width | 60~150mm |

Glue type | hot-melt glue |

Power Consumption | 6.5kw |

Total Weight | 4000kg |

Machine Size | 7500×2200×1500mm |

products diagram:

Suitable paper: kraft paper, art paper, white board paper, white cardboard (including laminated paper).

Surpporting machine: ZB50B Paper Bag Bottom Gluing Machine

verified

verified