Overview

Essential details

Warranty:

1 Year

Type:

Other

Applicable Industries:

Manufacturing Plant, Food & Beverage Factory

Showroom Location:

None

Video outgoing-inspection:

Provided

Machinery Test Report:

Not Available

Marketing Type:

New Product 2020

Warranty of core components:

1 Year

Core Components:

Motor, Pump

Condition:

New

Application:

Beverage

Packaging Type:

Bags, Film, Pouch

Packaging Material:

Plastic

Automatic Grade:

Automatic

Driven Type:

Electric

Voltage:

220V

Place of Origin:

Zhejiang, China

Brand Name:

HZPK

Weight:

300 KG

Dimension(L*W*H):

880*760*1800mm

Key Selling Points:

Long Service Life

Filling Accuracy:

99%

Bag Width:

40-150mm

Film Width:

100-320mm

Packaging volume:

50-500

Warehouse:

2188

After-sales Service:

online support, Video technical support

Supply Ability

Supply Ability

300 Set/Sets per Year

Packaging & delivery

Packaging Details

Our products are packed in boxs. We will check that if the machine can run before it is sent out. When you receive the goods, please open the package to check out if the goods are in good condition before the courier. If the boxs are damaged or other situations happen, please contact us in time.

Port

NIngbo port

Lead time:

Quantity(units) 1 - 5 6 - 20 >20 Lead time (days) 20 30 To be negotiated

Why Choose Us

1. More than 20 years manufacture in packing machine

2. 11 years alibaba supplier

3. 100% QC inspection before shipment

4. 12 months warranty

5. Product Certificated by CE

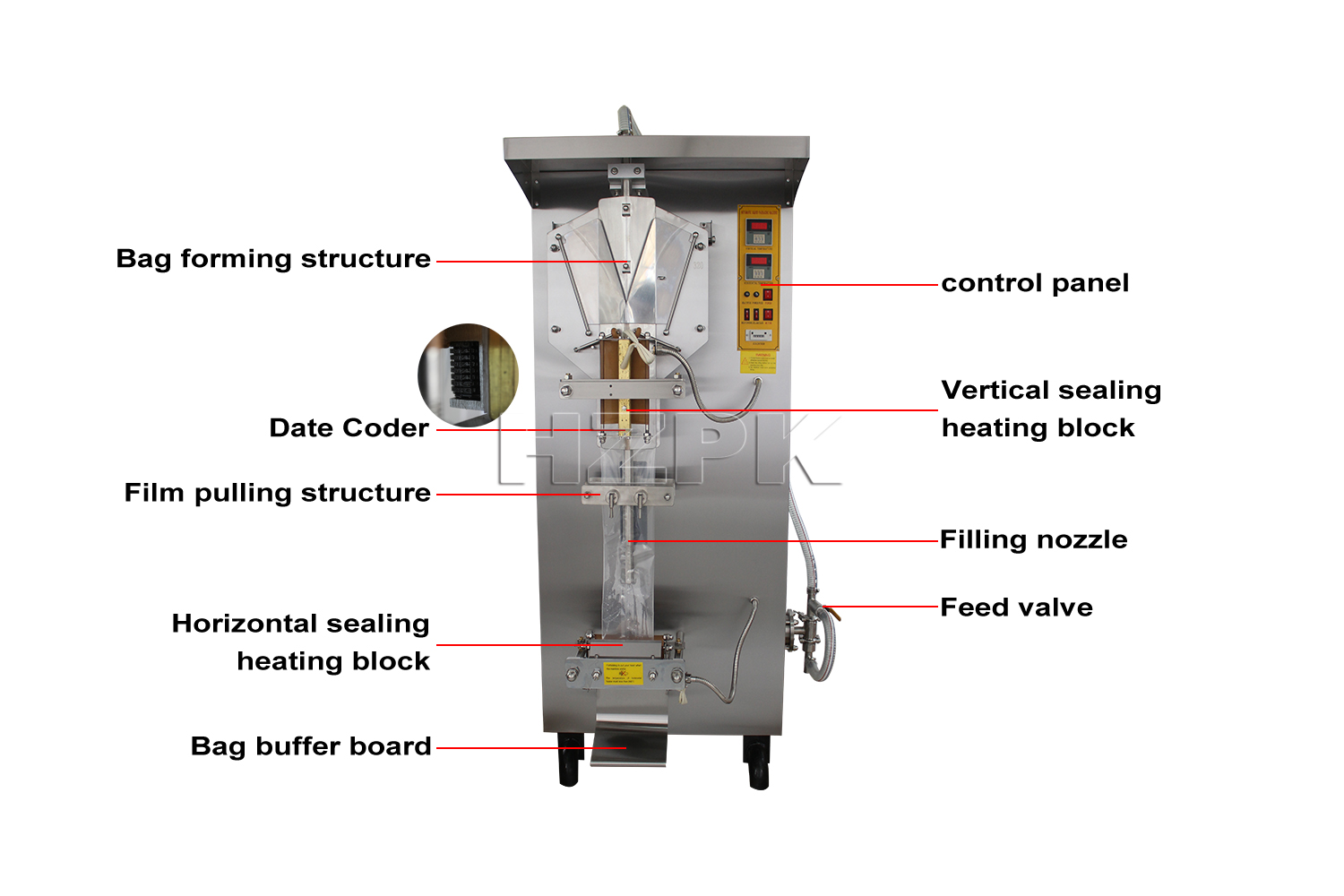

Product Description

Automatic plastic pouch liquid filling machine is applicable for filling and sealing liquid into bag, like water, juice, milk etc. It can automatically finish making-bag, metering, filling, sealing, cutting, counting and printing batch number.Features:1. frame and Liquid Contacting parts are 304 stainless steel. 2. Film output system: Composed of 304 stainless steel sliding rail plate. 3. Electrical control system: Composed of control panel, wiring, and the AC contactor system. 4. Equip UV sterilizer and date coder. 5. Data counting unit is equipped on the front panel.

Details Images

Bag Forming Structure

The film is passed through the forming structure and after sealing it will form the bag. The size of the bag can be controlled according to the film width.

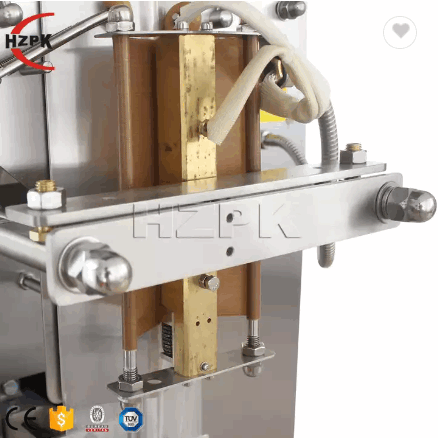

Vertical sealing

Pure copper heats up quickly.

Good thermal conductivity, zero deform

Coding part

Ribbon and steel stamp are available.

Bag pulling part

Pulling the bag smoothly with accurate length.

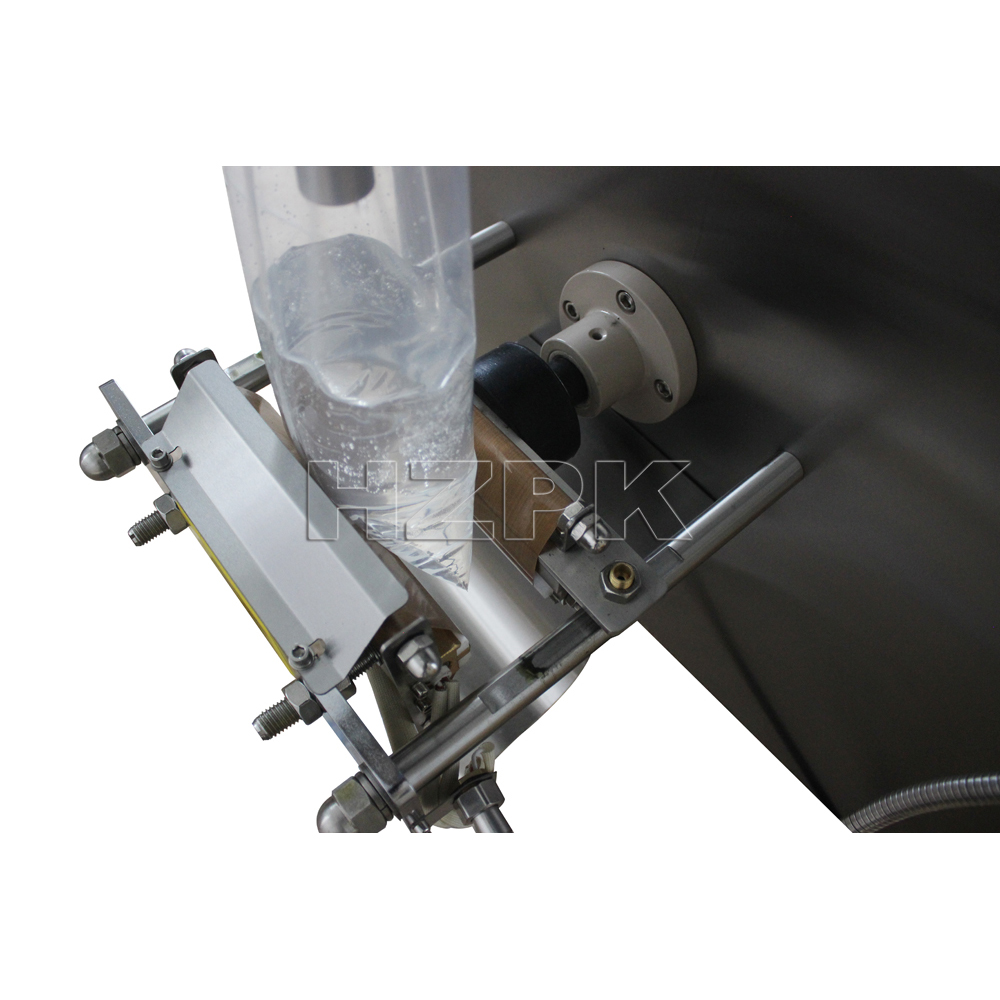

Sealing and Cutting

Pure copper heats up quickly, the seal is beautiful and firm.

Control Panel

Humanized design control panel, easy to operate Adjust temperature, automatic counting, germicidal lamp, etc.